I am just wondering why none of you turbo guys are running this? It is HUGE with the dsm crowd and I am sure it would help those of you on stock blocks significantly. It allows you to pull tons of timing without any knock whatsoever. It is actually hard to knock with E85. One of my friends here in town was able to push 656whp on 32psi out of a STOCK block 4g63. 130,000+ miles on it and no ported head. Bottom end had never been disassembled. Now granted they are turboed from the factory, I still think the 4g64 could push a lot more switching to e85 from pump gas. Its also cheaper than race gas and some people even switch to e85 from race gas because they think it is better.

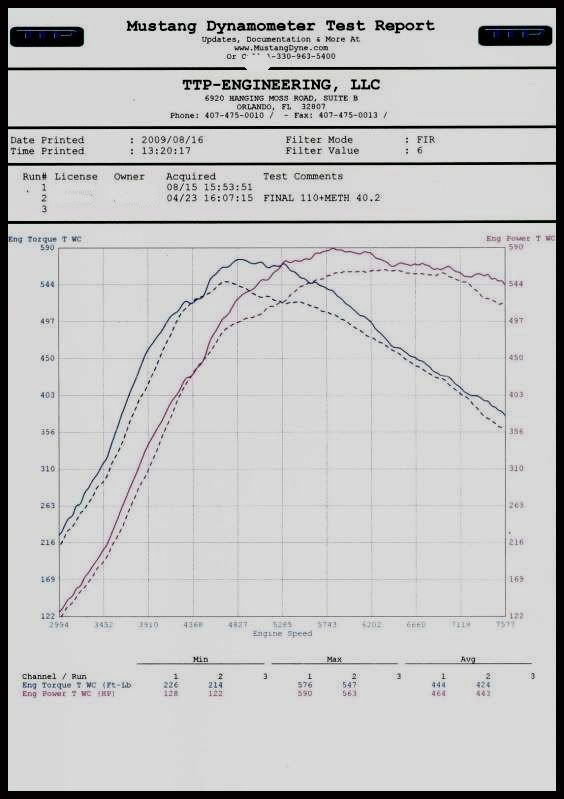

So has anyone ever ran e85 on their stock block 4g64? I would love to see the dyno results if so. If nobody has...why not?

So has anyone ever ran e85 on their stock block 4g64? I would love to see the dyno results if so. If nobody has...why not?